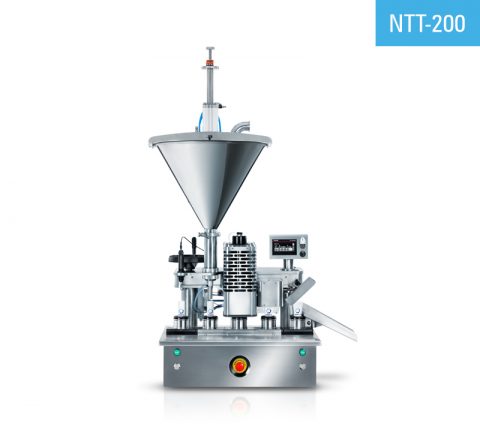

Tube filling and sealing machine, model NTT-200

The tube filling and sealing device NEWECO NTT-200 is used for filling of polyethylene and laminated tubes with gels, creams or other fluids, sealing them with hot air, stamping date and / or batch No. and cutting excess plastic on the tube ending, which arises during the tube sealing.

Key features of the semi-automatic tube filling and sealing machine:

- The semi-automatic tube filling and sealing machine is made of high quality stainless steel AISI 304

- All elements having contact with product are made of high quality stainless steel AISI 316

- Electronic control of sealing parameters and process

- Filling accuracy error: < ± 1 % of volume

- Hot air sealing technology

- Single or dual sided coding with set of fonts included

- Output of up to 700 tubes / hour

- The compact tube filling and sealing machine works with all plastic and laminated tubes

The budget tube filling and sealing machine is equipped with:

- Unitronics PLC controller

- MetalWork and Camozzi pneumatic elements

- Sensor of level of liquid in reservoir allowing for automatic filling up

- Air heater with automatic setting of temperature

- Counter of production output

- Tester of tube sealing strength

Level of automation of the small tube filling and sealing machine:

The operator loads empty tubes and positions them manually with the help of laser indicator. He then slides all tubes manually and presses two start buttons to initiate operation. The small tube filler and sealer automatically fills, seals, codes, and trims the tubes. The machine ejects closed tubes automatically.

Possible application of the cheap tube filling and sealing machine NEWECO NTT-200:

The cheap semi-automatic tube filling and sealing machine NTT-200 is used for packing of cosmetics, pharmaceuticals, chemicals and food products into tubes. The budget tube filling and sealing machine is designed to handle small and medium size batches / production lots / jobs. It can be used for regular production or for labs.

NEWECO – manufacturer of manual tube filling and sealing machines

NEWECO is a manufacturer of manual tube filling and sealing / crimping machines for thermoplastic (polyethylene (PE), laminated and other plastic) and aluminum tubes. All our machines are designed and manufactured in Poland in the European Union. Contact us to receive a price quotation. We do not trade with used machines / equipment, however we are convinced that you will find the prices / pricing of our new machines very attractive. Our machines and devices are designed and manufactured entirely in Poland (in the European Union).