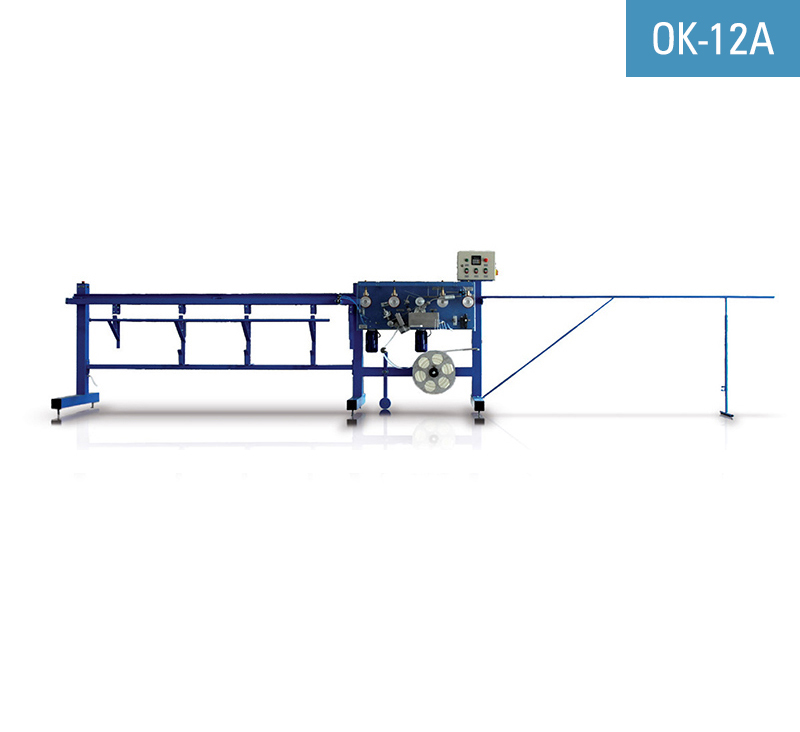

Machine adhering fiberglass mesh to corner beads, model OK-12A

The machine gluing fiberglass mesh to angle beads, model OK-12A is used for adhering fiberglass mesh to PVC, aluminum or stainless steel corner beads with the use of hot melt adhesive. Machine used for manufacturing of corner beads with fiberglass mesh can work in semi-automatic mode, as well as in automatic mode (with the automatic corner beads feeder PN-200).

Key features of the machine used for manufacturing of corner beads with fiberglass mesh:

- System of control of mesh stress and automatic adjustment of feed rate, which stabilizes production process and significantly improves quality of end-product

Main elements of the machine sticking fiberglass mesh to corner beads:

- Unitronics PLC controller

- Control sensor of mesh placement

- Reservoir of hot-melt glue with isolation protecting an operator from heat injuries

Level of automation of the machine adhering fiberglass mesh to corner beads:

The machine adhering fiberglass mesh to corner beads can work in:

- Semi-automatic mode: all operations except for feeding of corner beads are done automatically. In this setting the machine can be operated by one or two operators.

- Automatic mode: with the automatic corner beads feeder PN-200. In this setting both machines can be operated by one operator.

NEWECO – manufacturer of machines adhering fiberglass mesh to corner beads

NEWECO is a manufacturer of machines adhering fiberglass mesh to corner beads, drip profiles and window profiles (reveal beads). Contact us to receive a price quotation. We do not trade with used machines / equipment, however we are convinced that you will find the pricing of our new machines very attractive. Our machines and devices are designed and manufactured entirely in Poland (in the European Union).